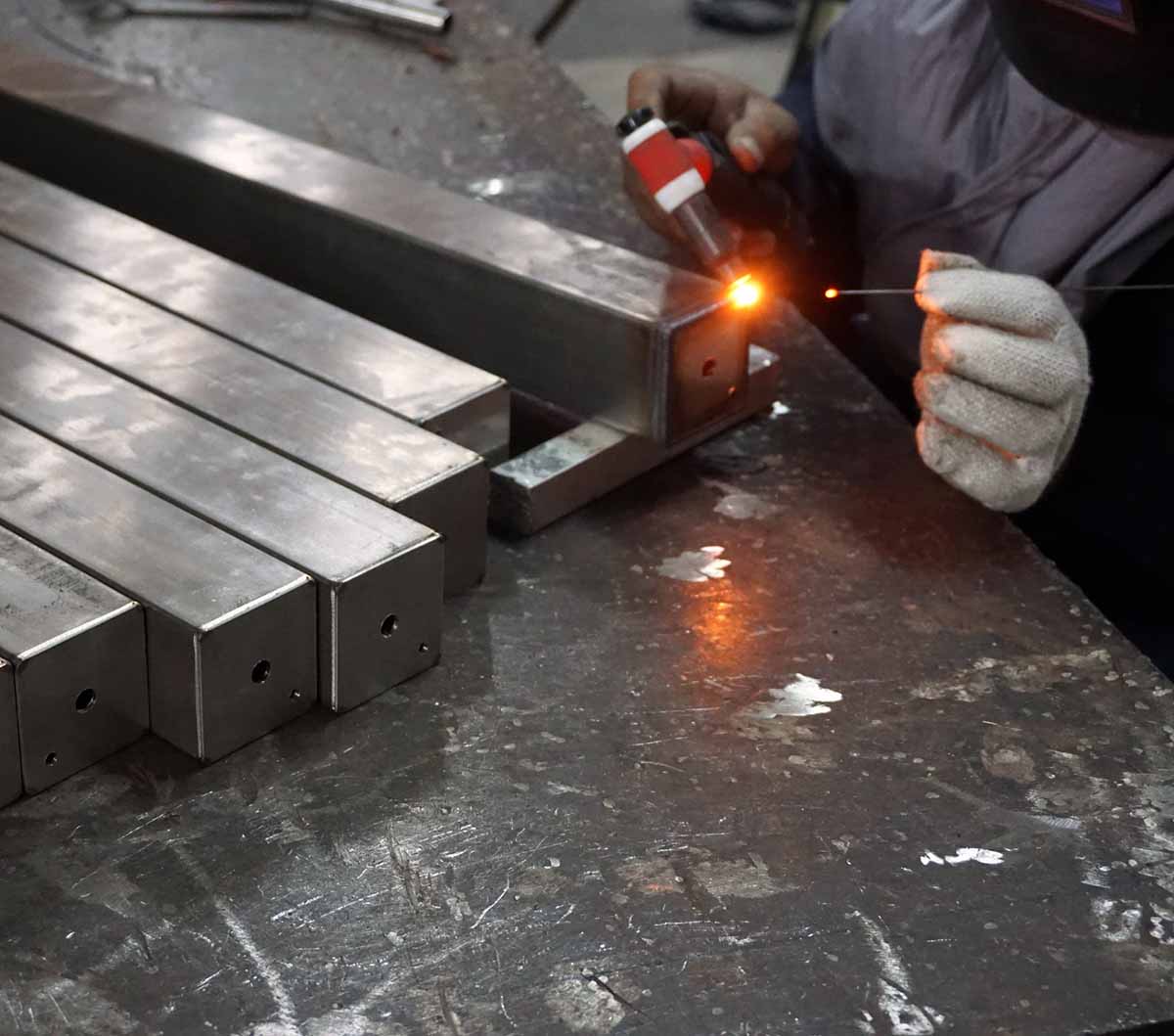

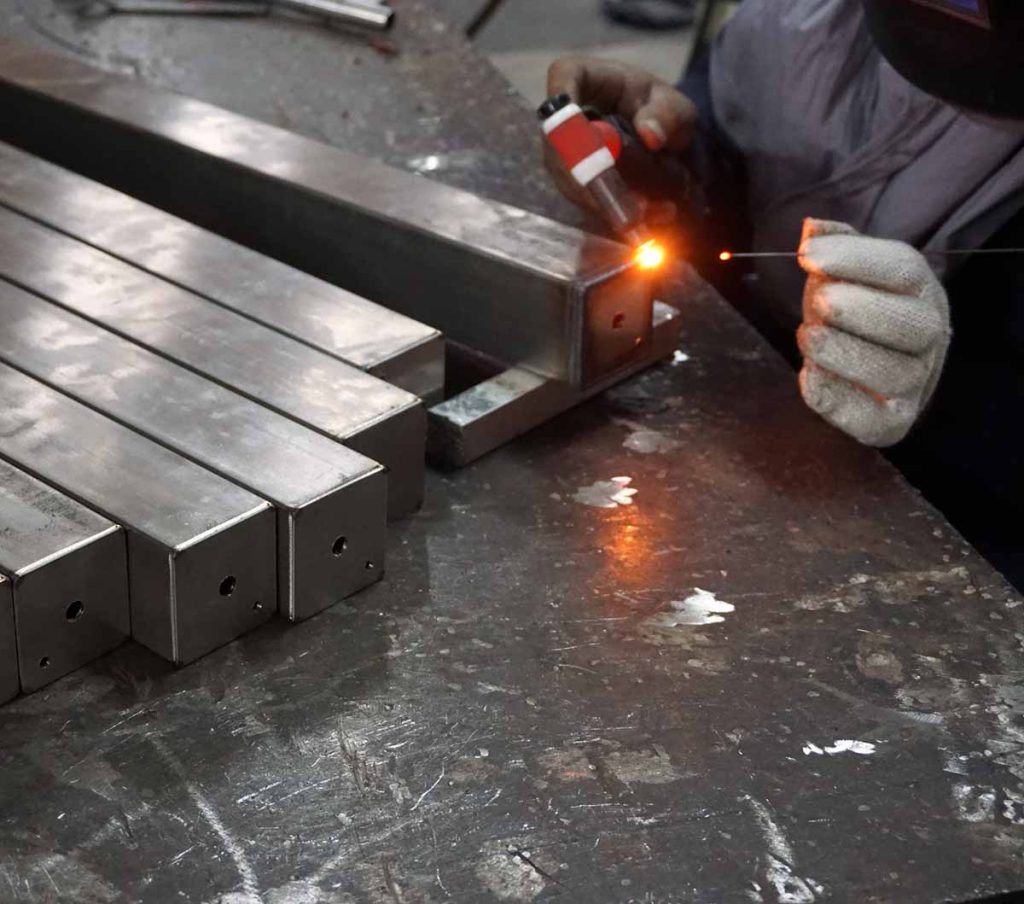

We provide exceptional stainless steel welding services for residential and business customers throughout the St. Louis area.

When it comes to projects demanding strength, resilience, and a touch of elegance, stainless steel is the material of choice. At Pinnacle Metal Works & Contracting, we take great pride in offering top-notch stainless steel welding services that elevate your construction and manufacturing endeavors to new heights.

Call for a Free Estimate.

Unparalleled Expertise

Pinnacle Metal Works & Contracting brings nearly two decades of experience in stainless steel welding to St. Louis and the surrounding areas. Our team consists of highly skilled welders who are experts in working with stainless steel. This alloy’s unique properties require specialized knowledge to ensure high-quality welds and finished products.

The Versatility of Stainless Steel

Stainless steel is an exceptionally versatile material, making it suitable for various applications. It’s well-known for its corrosion resistance, durability, and aesthetic appeal. There are different types of stainless steel. The most commonly used stainless steel alloys include:

- Austenitic Stainless Steel: These are non-magnetic and offer excellent corrosion resistance. They are often used in applications such as food processing and medical equipment.

- Ferritic Stainless Steel: Ferritic stainless steels are magnetic and less corrosion-resistant than austenitic ones. They are suitable for applications that do not require high corrosion resistance, such as automotive exhaust systems.

- Martensitic Stainless Steel: Known for its hardness and durability, it is used in cutlery and tools.

- Duplex Stainless Steel: These alloys combine the qualities of both austenitic and ferritic stainless steels, providing a balance of strength and corrosion resistance. They are used in marine and petrochemical industries.

Welding Techniques for Stainless Steel

Welding stainless steel requires precision and care to maintain its corrosion resistance and structural integrity. Several techniques are commonly used:

- TIG Welding: TIG welding, also known as GTAW (Gas Tungsten Arc Welding), is the most popular method for welding stainless steel. It involves using a non-consumable tungsten electrode and a filler material with a shielding gas to protect the weld from atmospheric contamination. TIG welding produces clean, high-quality welds, making it suitable for applications where aesthetics are crucial, such as architectural structures and food processing equipment.

- MIG Welding: MIG welding, or GMAW (Gas Metal Arc Welding), is another common technique for stainless steel. It uses a consumable wire electrode and a shielding gas to protect the weld. MIG welding is faster than TIG welding and is often used in manufacturing applications.

- Stick Welding: Stick welding, or SMAW, is less common for stainless steel but is still used in some applications. It involves a coated electrode suitable for thicker stainless steel materials or field welding.

Choose Excellence with Pinnacle Metal Works & Contracting

When it comes to stainless steel welding services in St. Louis, Pinnacle Metal Works & Contracting is the name you can trust. Our commitment to expertise, precision, and quality ensures that your projects meet and exceed expectations. Whether you’re designing an architectural masterpiece, need industrial-grade equipment, or require precision manufacturing, we have the knowledge and skill to make it happen. Elevate your projects with stainless steel welding from Pinnacle Metal Works & Contracting.